AFT Blog

Two for One: How Dependent Design Cases Help Automatically Size Networks to Satisfy Multiple Operating Scenarios

With the release of the Automated Network Sizing (ANS) module for AFT Fathom and AFT Arrow, network sizing has never been easier. The ANS module utilizes Intelliflow, a technology previously featured in AFT Mercury and Titan, to evaluate slight design deviations to automatically size pipes, valves, and pumps for a system as a whole.

In a project's design phase, the base ANS module can test hundreds of scenarios to settle on a case which can minimize design objectives such as system weight or cost while maintaining user-specified design requirements. These design requirements could include minimum or maximum pressures, flowrates, and velocities throughout the system. Automatic sizing is straight-forward for a single set of operating conditions, but what if your system must operate in several design cases? Here are a few potential examples to consider:

- A vessel is charged to different pressures throughout the day.

- A sprinkler system with different summer and winter demands.

- A pilot plant with established plans for an expansion.

- A housing water network which must meet standard operating conditions with the capability to handle fire hydrant surges.

Within the ANS module, a dependent design case is a useful way to size a single system for a diverse set of operating conditions to ensure all design requirements in all scenarios are met.

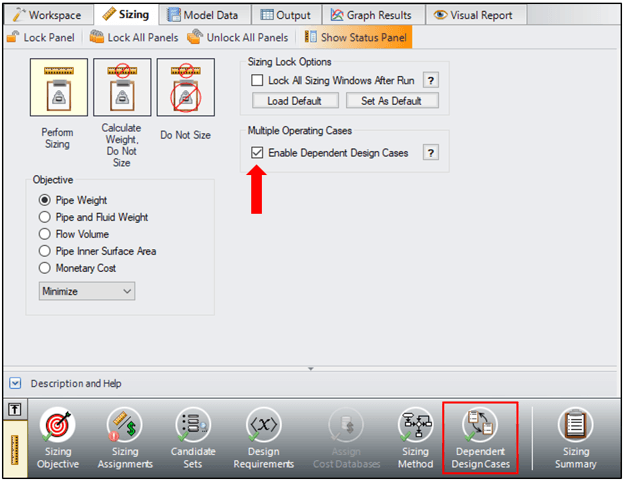

To begin using dependent design cases (DDCs), you must first enable them by checking the box on the Sizing Objective panel in the Sizing window.

Enabling DDCs will add the Dependent Design Cases panel to the Sizing Navigation Panel. We won't worry about that just yet.

First, we want to duplicate the base system so the DDC's design requirements and operating conditions can be varied independent of the base case.

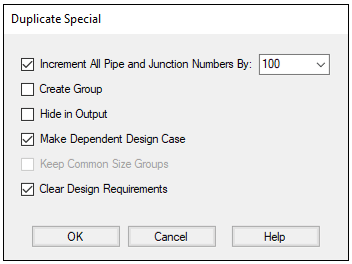

To create a DDC, begin by highlighting the entire base system, then select Edit>Duplicate Special which will bring up the following screen:

In the Duplicate Special window, I recommend checking most of these boxes for different reasons.

- Increment All Pipes makes it clear in output which pipes are linked to one another.

- Create a Group will make it easier to select the DDC in later steps, but also provides a chance to label different DDCs internally in addition to using annotations.

- Hide in Output will limit the output if you wish to clean up the output data. However, I recommend leaving this unchecked to ensure the DDC produces reasonable results.

- Keep Common Size Groups is assumed for a Dependent Design Case to ensure continuity between the different cases.

- Clear Design Requirements is useful if there are no overlapping conditions between the two cases. Personally, I would clear them and ensure the case is exact to the desired specifications.

After creating the dependent design case, the system can now be re-specified for another operating condition. This could include re-specifying pressure and flow junctions, varying a valve closure, bringing pumps online, or even adding pipes to a DDC to represent a planned future expansion.

Be wary of adding pipes to a DDC however as the total cost will include all pipes which are sized, even those added exclusively to a DDC case. Also, be careful when modifying the base system after creating the DDC as DDCs do not act like child scenarios. The ANS module uses DDCs to concurrently size a system for both operating conditions. This requires that the pipes paired between both the base system and dependent design case are identical regarding properties like pipe length and pipe material.

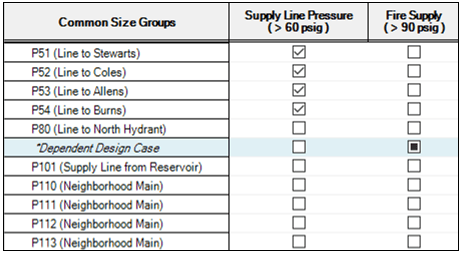

With the DDC model re-specified, we can also add new design requirements in the Design Requirements panel to reflect the case-specific goals. After specifying the new design requirements, they can be assigned specifically to pipes created in the Dependent Design Case, as seen below:

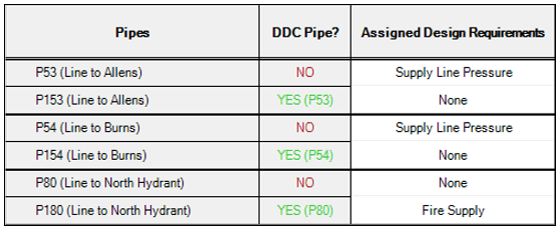

A further check on which design requirements apply in which case can be found in the Dependent Design Cases panel (I told you we'd get back to that!). This panel also indicates pipes are related to one another, as well as the assigned design requirements for each.

With the DDC fully specified, we can run the model and sit pretty knowing our system was properly sized for ALL of its operating conditions.

You may be asking yourself: Wouldn't the system cost be double since we duplicated the model? In this case, the ANS module only reports one cost because the systems are expected to be identical. The creation of a DDC is limited to varying operating conditions to ensure this continuity across cases. The ANS module cannot account for changes such as pipe length or pipe material for paired pipes across cases because this implies the two models are not identical. Any attempts to change a material specification in a DDC will cause AFT Fathom to create an alert of the discrepancy between cases and will not proceed with a run. However, the ANS module can handle the addition of pipes to a DDC to account for future planned expansion. The costs of a planned expansion in a DDC will be included in the reported cost, so be aware that the cost in planned expansion cases is not the same cost as for the base system.

You may also be asking yourself: What if I am modeling a compressible gas system? Well, good news! You can use the ANS module for AFT Arrow to meet all your automatic sizing needs.

For more information about how you can make Dependent Design Cases work for you, check out the Help Guide articles (located within the Help section of the software) "Multiple Operating Cases" and "Dependent Design Cases Panel".

If you want an easy example to follow of the process, look for the Multiple Design Case Example in the Automated Network Sizing Module Quick Start guide. If you have further questions regarding the ANS module and DDCs, we'd love to hear them at This email address is being protected from spambots. You need JavaScript enabled to view it..

Comments