AFT Blog

Smarter Thermal Modeling: Enhanced Heat Exchanger Options

Accurately modeling heat transfer in piping systems is critical to designing systems that perform reliably under real-world conditions. In fluid systems where temperature affects safety, efficiency, or performance – such as in chemical processing, energy generation, or HVAC – heat exchangers often play a central role. That's why engineers turn to advanced simulation tools to get the thermal side of their designs right.

With the release of Fathom 14 and Arrow 11, Datacor Pipe Flow Modeling introduces a major enhancement: expanded heat exchanger modeling capabilities that allow users to represent how heat transfer performance changes with flow rate. These new options provide a more realistic and flexible way to simulate thermal behavior – without the need for extensive user-supplied data.

A Look at the Legacy Approach

Historically, Fathom and Arrow supported a broad set of heat exchanger models using two general methods:

- NTU-Effectiveness Models: Including counter-flow, parallel flow, shell-and-tube, and various crossflow configurations.

- Direct Specification Models: Where thermal properties like heat rate or outlet temperature were entered directly by the user.

The NTU-Effectiveness method is a widely used and reliable approach when inlet and outlet temperatures are unknown. These models determine heat transfer by calculating the effectiveness of the exchanger – essentially the ratio of actual to maximum possible heat transfer based on fluid conditions. However, they require users to input a constant value for the overall heat transfer coefficient (U), which does not change with flow.

In real-world systems, though, heat transfer performance is rarely constant. It depends on many factors – especially flow rate, which influences the convection coefficients on both the primary and secondary fluid sides. Engineers often had to rely on approximations or oversimplified assumptions to account for this.

What's New in Fathom 14 and Arrow 11

The new Enhanced Heat Exchanger Modeling tools address this limitation by offering two new options specifically for NTU-Effectiveness models:

1. Estimated Overall Heat Transfer Coefficient

This option dynamically estimates the heat transfer coefficient based on a single operating point. Users specify U at a reference flow rate, along with an exponent (N) that reflects the geometry of the heat exchanger.

Behind the scenes, the software uses the known relationship between flow (specifically Reynolds number) and convection to estimate how U will vary across different flow conditions. For example:

- N = 0.8 for turbulent flow in smooth tubes

- N = 0.4–0.8 for shell-and-tube exchangers, depending on baffle and flow arrangement

This method is ideal when you don't have detailed curve data but still want to capture how heat transfer performance varies across operating conditions.

Additionally, the Estimated U method is compatible with the Thermal Link feature—whether you're using it to connect two heat exchangers within the same model or to couple Fathom and Arrow in a cross-application setup. Because convection coefficients on both the primary and secondary fluid sides are adjusted based on flow rate, coupling these features together allows for a more accurate and detailed calculation of the overall heat transfer coefficient.

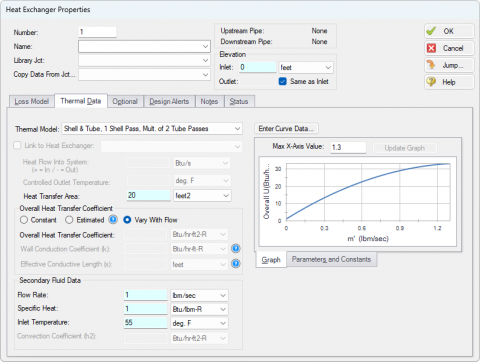

2. Vary Overall Heat Transfer Coefficient With Flow

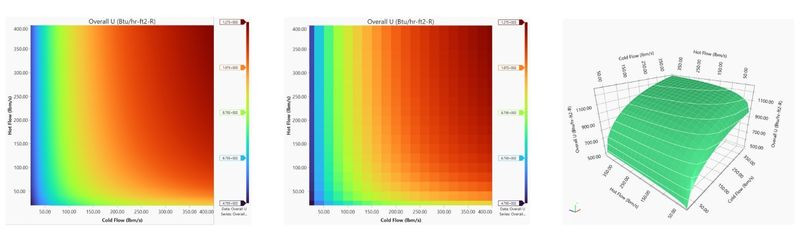

This second option provides a direct way to define how U varies with flow by entering a U vs. flow rate curve. Similar to entering pump or resistance curves, users can specify a series of data points and fit a polynomial or apply linear interpolation. This gives engineers precise control over how U responds to changing flow.

This option is not compatible with Thermal Link, which assumes a constant U or requires calculation from dynamically estimated convection coefficients on both sides. However, it's a powerful tool when you have empirical U data and want to capture nonlinear thermal behavior directly.

Why These Updates Matter

These two new modeling approaches offer substantial benefits for engineers working with heat exchangers in complex or variable-flow systems:

- Greater realism – Accurately model how heat transfer changes with operating conditions.

- Improved accuracy – Avoid oversimplified assumptions that could lead to design errors or missed optimization opportunities.

- Streamlined workflow – Use fewer manual iterations when modeling heat exchangers across multiple scenarios.

- Deeper integration – When using Estimated U in combination with Thermal Link, both convection sides of the heat exchanger respond dynamically to flow changes, allowing the model to reflect the physical coupling between the primary and secondary fluids. Because heat transfer depends not only on convection on each side but also on conduction between them, this interaction enables a more complete and nuanced representation of thermal behavior.

Whether you're designing a cooling loop, evaluating process plant performance, or modeling a transient gas-liquid interaction, these tools help you build simulations that reflect reality more closely – ultimately leading to smarter decisions and better-performing systems.

Getting Started

To take advantage of these features:

- Open a heat exchanger's Thermal Data tab.

- Choose either Estimated U or Vary With Flow from the modeling options.

- Enter your reference values or curve data.

Fathom 14 and Arrow 11 continue to expand the boundaries of what's possible in pipe flow modeling. With the newly enhanced heat exchanger modeling, you can now simulate thermal performance with more flexibility, precision, and confidence than ever before.

Comments