AFT Blog

You're tasked to perform a transient analysis of a piping system and it would be really helpful if there was a good software tool out there to help you. Well, you've come to the right place because AFT has great solutions! But our first question is, "What kind of transient analysis are you trying to do?" You might s...

Jack, Ryan, and Sally are piloting a small research vessel on a remote river. While distracted by news of the Mars 2020 Perseverance rover (successful landing!), their vessel crashes and begins capsizing. After their initial panic, they are dismayed to find the collision has taken out their communications equipment.

In some quick thinking, Jack finds a printed log of ships expected to be nearby. Fortunately, there is a marine zoology expedition about a mile downriver, and our crew just needs to get an SOS out to that ship.

Initially, Jack tries simply yelling for help. Unfortunately, this doesn't do much good - and the explanation why requires some fluid mechanics.

In the final "Know Your Pump & System Curves" blog series, I am going to discuss the complexities behind pump vs. system curves for systems with pumps in series and parallel configurations. Multiple pumps in series configurations are relatively straight-forward and will be discussed briefly. Operating pumps in parallel configuration involve a f...

In this blog, we dive further into pump and system curves for complex systems. The examples include demonstrating system curves changing over time and when multiple system curves exist for a single system with multiple pumps in different locations of the system. Let us re-visit the multi-branched system example from the previo...

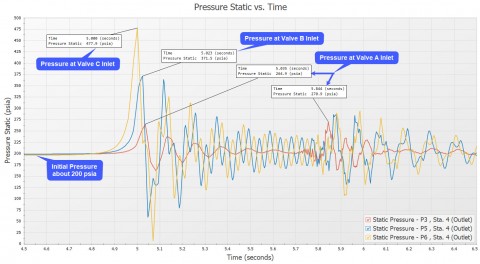

In June 2020, AFT's Reinaldo Pinto presented the webinar Calculating Transient Forces for Pipe Stress Analysis. The webinar focused on generating unbalanced forces due to surge in AFT Impulse and exporting them to CAESAR-II. During the webinar, 28 questions were asked. Below are the responses. Download the presentation: www.aft.com/...

Many users enjoyed my previous blog, "Know Your Pump & System Curves – Part 1" and greatly anticipated the release of Part 2. I'm going to split Part 2 into two separate blogs: Part 2A Brief discussion on why system curves matterPump & System Curves for multi-branched piping systems§How you can have different system curves for the...

Almost every piping system has valves, and an accurate solution requires accurate valve losses. For incompressible systems, this is relatively straightforward. What happens when we introduce the complexities of compressible flow?