AFT Blog

NPSH got you under pressure? This’ll get you pumped!

Cavitation is an important subject in piping systems. Quite often, cavitation is an operating condition that is to be avoided, such is the case with pumps. Not only can cavitation cause serious decreases in pump performance, but it is also a maintenance nightmare if left unaddressed. Such issues are costly and may lead a system to be deemed unsafe.

As you are likely aware, cavitation exists when the local pressure falls below the vapor pressure of operating fluid. Overtime the pressure may increase again so that the cavity formed then collapses. When this collapse occurs on the vanes of a centrifugal pump, the over pressure from the collapse could cause erosion. It is this erosion that can lead to unforeseen shutdowns and additional costs for pumping equipment hardware, namely a new impeller. Figure 1 below shows the negative impact erosion can have on rotating equipment like pumps.

Figure 1 Erosion in rotating equipment.

Cavitation, although frequently transient in nature, can occur in the steady state too. One common area is the pump itself. This cause of cavitation is commonly described and understood through the concept of net positive suction head, or NPSH. In short, NPSH is a margin between the pressure available to the pump and the vapor pressure of the fluid. There are two values related to NPSH that are very useful in avoiding cavitation in pumps, net positive suction head available and required.

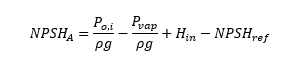

The net positive suction head available, NPSHA, is a measure of the total head available at the suction of the pump minus the vapor pressure of the fluid. The head available accounts both for the static and the dynamic head. This value, , is greatly impacted by upstream conditions such as liquid level of the pump’s supply reservoir and the characteristics of the suction piping. The vapor pressure of the working fluid in terms of head, , is this then subtracted from this value to find the available net positive suction head at the pumps suction. See the general equation below.

![]()

The net positive suction head available at the suction tells the engineer or operator how far the fluid at the pump suction is from cavitation, however it does not fully account for the pumps performance downstream of the suction. This point is also referred to as the “eye” of the pump in literature. It is not enough to simply have the NPSHA value to be confident the pump will not cavitate. The required NPSH, NPSHR, is also necessary.

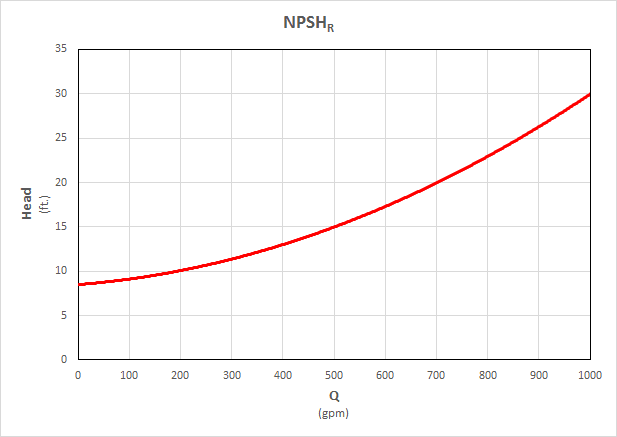

Pumps vendors typically put their products through rigorous testing regimes and can provide valuable data to their prospective customers because of these tests. The required net positive suction head to avoid cavitation in the pump at varying operating points is commonly part of this information. Many vendors, not all of them, use the “3%”-rule, that states cavitation has begun to occur inside the pump when the pump’s head rise drops by three percent. This information is presented in the form of NPSHR curves, as shown below, and can be quite variable as a function of flowrate. Armed with the required NPSH curve and the available NPSH, operator and engineers can then verify whether their pump will be experiencing cavitation during operation. A pump will not cavitate so long as the NPSHA is greater than NPSHR.

Figure 2 A sample net positive suction head required curve.

This is where AFT Fathom provides great value in protecting your pump. AFT Fathom 9 will calculate the available net positive suction head and allows the user to input the required curve as well. Curves that are input are also able to be adjusted with changes in the pumps speed as well. Using the information of the system configuration and the calculated results, Fathoms predicts the NPSHA through the following equation and the NPSHR from the curve data:

In the above equation, is the stagnation pressure at the inlet of the pump. This can be found by looking at the outlet of the suction pipe for the pump. By using the stagnation pressure, the dynamic and static heads are already accounted for. Next, , the vapor pressure can be located under the system properties. This is converted in to terms of head by dividing by the fluid density and the gravitational acceleration constant. Mars users beware! is of course the inlet elevation of the pump, the center of the suction’s height. And finally, , is the reference height for the pump. This value is typically the centerline of the pump, but for pumps that have different inlet and exit heights, the value represents the physical height in the pump where the required NPSH curve was created from. Again, if the pump has the same elevation for suction and discharge this value is equal to the inlet elevation of the pump and the terms are negated. It is typical that this value resides in between the absolute elevation of both the discharge and suction side of the pump. In AFT Fathom the reference NSPH value may only be entered if users have elected to specify two different elevations for this points.

Users concerned with modeling variable speed pumps should also be aware of the affinity exponent feature. The NPSHR curve does not necessarily follow the affinity laws at integer powers and this feature allows the user to adjust accordingly. Found on the Pump Configuration window, the exponent is used when varying speeds are entered or calculated, as in the case of control set point models.

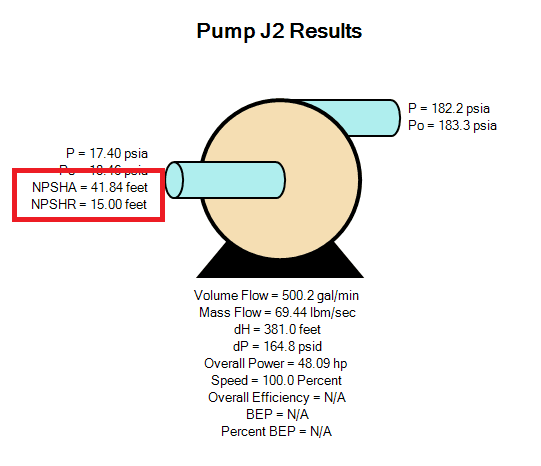

The Output Results primary window contains all the above information, and a hand calculation can be done to verify the calculations of the software if needed. Additionally, entering the NPSH required curve will also allow users to easily juxtapose the available and required NPSH quickly, to ultimately determine if their pump will cavitate. The image below shows a sample Pump Results Diagram found in the Output Results window.

Figure 3 The results diagram from the Output Results window in AFT Fathom 9.

If the available NPSH is in fact not greater than the required NPSH, there are a few options available to address this issue. The first of which, is to increase the liquid level of the sump. This of course will provide a greater hydrostatic head. As this is not always an option, the surface pressure of the sump reservoir may also be increased. This is not suitable for applications with sump reservoirs open to atmosphere however. Changing elevations may also be a solution. Either the pump skid may be lowered or the reservoir raised, if it is a tank and easily moved. Existing systems may prove too difficult to relocate these pieces of the system in regards to grade though. There are also situations that arise where filters that are in place to protect pumps from particulates, are too stringent in their flow capacities. Choosing a different filter can alleviate this problem. Another option, under reasonable circumstances, is to install a similar filter in parallel to the existing one. This will lower the respective flowrates through the filters and thus, the pressure drop across them.

Catering to adjustments in the available net positive suction head is more readily accomplished, as opposed to changing the required net positive suction head. Changing the required NPSH is only accomplished by altering the pump itself. This creates a different performance altogether, but may be more reasonable if the pump has not yet been selected.

Firm understanding and characterization of net positive suction head can enable those involved with system design or operation to protect their pumps. This of course can lead to significantly reduced maintenance costs, improved performance, and possibly code compliance. Hydraulic modeling software such as AFT Fathom 9 can make quick work of these calculations and give engineers and operators the tools they need to improve their systems. Make sure your pump won’t cavitate today by modeling your system in AFT Fathom 9!

Comments