AFT Blog

Sonic Choking: Flow Areas vs. Sonic Areas

AFT Arrow can be used to model various types of choking such as restriction choking, endpoint choking, and expansion choking. A useful parameter in AFT Arrow’s output is the “Sonic Flow Area” and this is the flow area in which sonic choking will occur. Comparing the sonic flow area to the actual flow area can help determine the margin between not choking and choking.

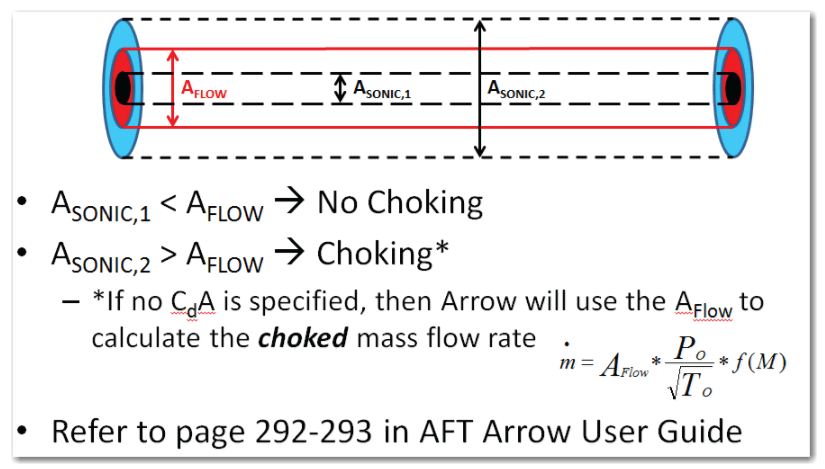

The figure below provides a conceptual understanding of comparing various sonic areas to the actual flow area of a compressible system. If one defines their system such that the sonic area (ASonic,1) is less than the flow area, the portion of the system will not choke. If the sonic area (ASonic,2) is greater than the flow area, then there will be choking.

In summary, to avoid choking, adjust the flow area such that it is greater than the sonic area.

Comments 2

Ben,

How do you obtain the CdA value (minimum possible flow area)?

Hi Bogdan,

The CdA value is essentially an effective flow area and it can typically be somewhere between 90-95% of the orifice area itself.

That being said, determining what the actual CdA value is can be challenging. Manufacturers may not always be able to provide a CdA value either.

Here is a white paper we've written that goes into detail regarding how to determine the Cd value and hopefully this will provide some guidance for you, https://www.aft.com/documents/AFT-Modeling-Choked-Flow-Through-Orifice.pdf.