AFT Blog

Dynamic Mixing Calculations in AFT Arrow

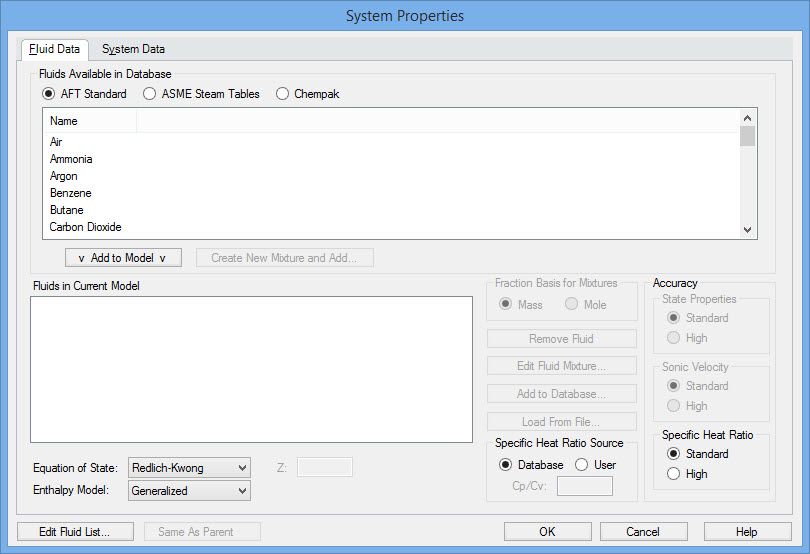

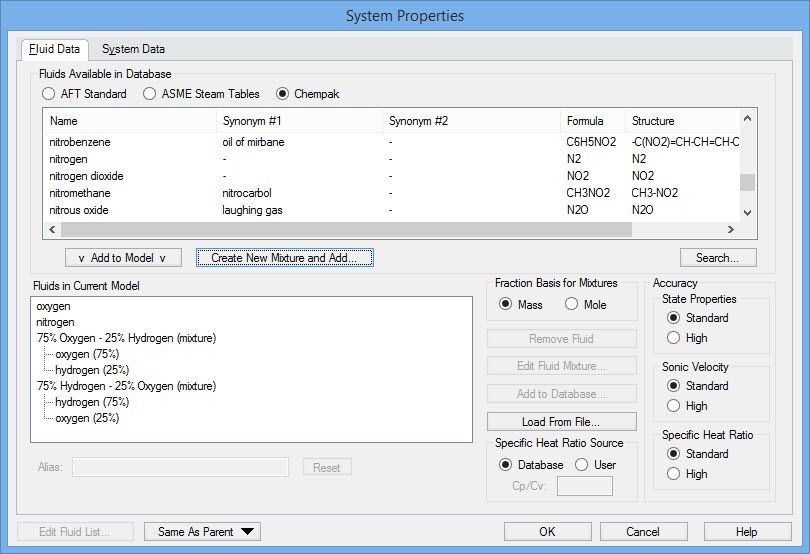

In AFT Arrow, there are three types of fluids that can be modeled: AFT Standard, ASME Steam, and Chempak. The focus of this article will be on how to use the Chempak Database with AFT Arrow in order to perform dynamic mixing calculations. But first, I would like to briefly introduce each of the three types of fluids that can be modeled in AFT Arrow.

The gases in the AFT Standard fluid list are included with the standard AFT Arrow software. Various equation of state models are available including Ideal Gas, Constant Z, Three Parameter, and Redlich-Kwong. There are also multiple enthalpy models available such as a Generalized enthalpy model, Reference enthalpy, and a Table look up of enthalpy values. Any customized fluid that the user creates will also appear in the AFT Standard fluid database in AFT Arrow.

The ASME Steam Tables fluid type allows more accurate thermo-physical property modeling of steam with the ASME Steam Tables of 1997. In addition to a higher level of accuracy, the ASME Steam Tables also have information about the saturation lines. So if the system fluid temperature is lower than the saturation temperature, then the user will be alerted of this, as the fluid will be condensing, and AFT Arrow does not model two phase flow. The ASME Steam Tables are also included with the standard AFT Arrow software.

The third fluid option in AFT Arrow is to use the Chempak Database, which contains accurate thermo-physical properties for over 600 different fluids. The fluids in the Chempak Database also have saturation conditions built in so that if the temperature drops below the saturation temperature, the user will be alerted. The Chempak Database must be purchased separately to use with AFT Arrow.

For more details about each type of fluid, please refer to the AFT Arrow Help File. Here is another blog article that discusses the accuracy options that can be used, https://www.aft.com/blog/entry/2013/06/24/using-standard-accuracy-specific-heat-ratio-to-solve-aft-arrow-convergence-problems.

Now, time to get down to business regarding how to perform dynamic mixing calculations in AFT Arrow. Dynamic Mixing in AFT Arrow means that you can have multiple flow streams in different branching sections of a system where each different flow stream is made up of a different fluid. Once each individual fluid mixes together at a common mixing point, AFT Arrow will accurately calculate all the flow rates, pressures, temperatures, and thermo-physical properties downstream of the mixing point, as well as the mixed fluid compositions! This is a very powerful feature of AFT Arrow that allows one to take their compressible flow modeling even further.

In order to perform the dynamic mixing calculations, the Chempak Database (sold separately) MUST be used. AFT Arrow does NOT perform dynamic mixing calculations with AFT Standard fluids or ASME Steam, ONLY the Chempak Database.

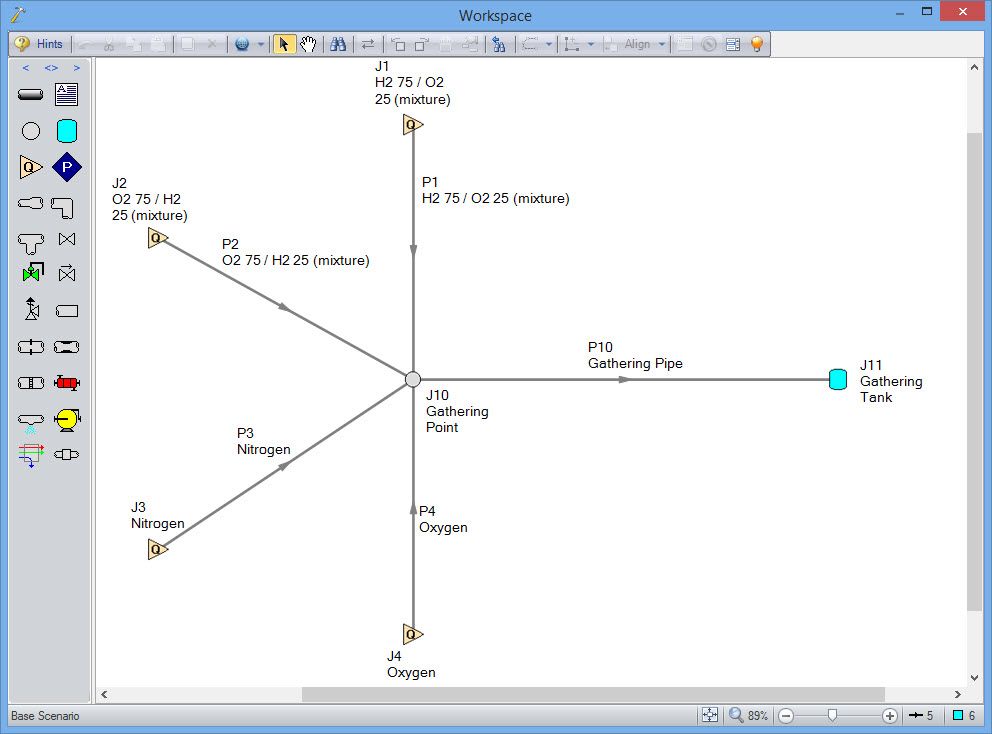

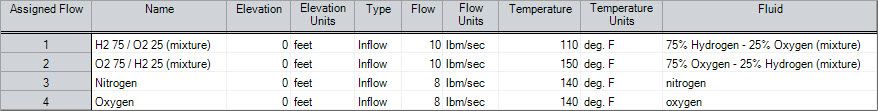

Setting things up for the dynamic mixing calculations is very straight-forward. Consider the system below where there are four separate pipelines that contain the following gases: a mixture of 75% hydrogen and 25% oxygen, a mixture of 75% oxygen and 25% hydrogen, pure nitrogen, and pure oxygen. The gases in each flow-path will combine and mix at the Gathering Point (J10) before the final mixture is delivered to a Gathering Tank downstream.

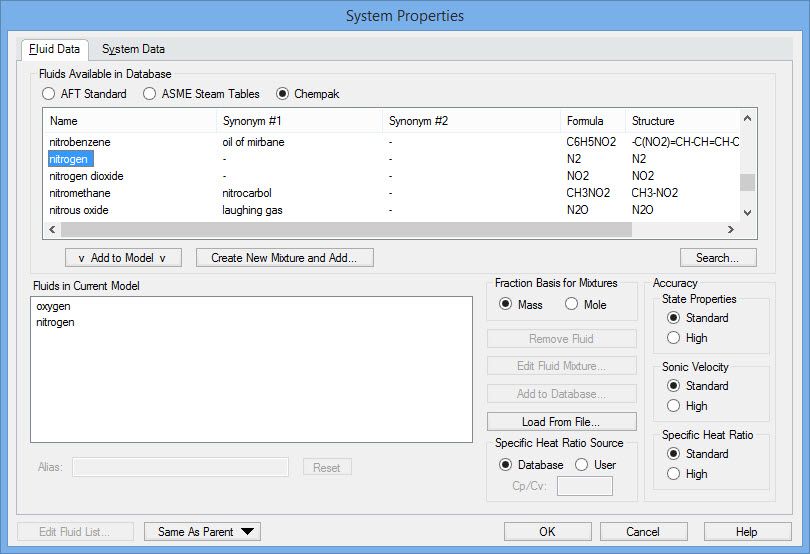

After the input for all the pipes and junctions is defined, the individual fluids for each flow stream can be defined in the System Properties window using the Chempak option.

We will start with adding pure oxygen and pure nitrogen to the list of Fluids in Current Model. Simply locate the fluid in the list and add it to the model, as shown below.

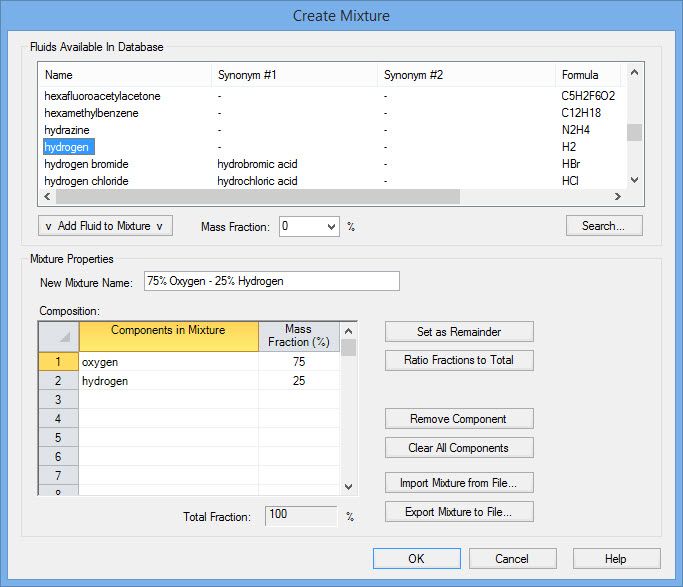

The remaining fluids to define for the model below are mixtures based upon a mass fraction. Click on the “Create New Mixture and Add” button, and then define each fluid mixture with a name and a composition.

- 75% Oxygen – 25% Hydrogen (mass fraction)

- 75% Hydrogen – 25% Oxygen (mass fraction)

After all the fluids are defined, they will be displayed in the list on the Fluid Data tab of the System Properties window.

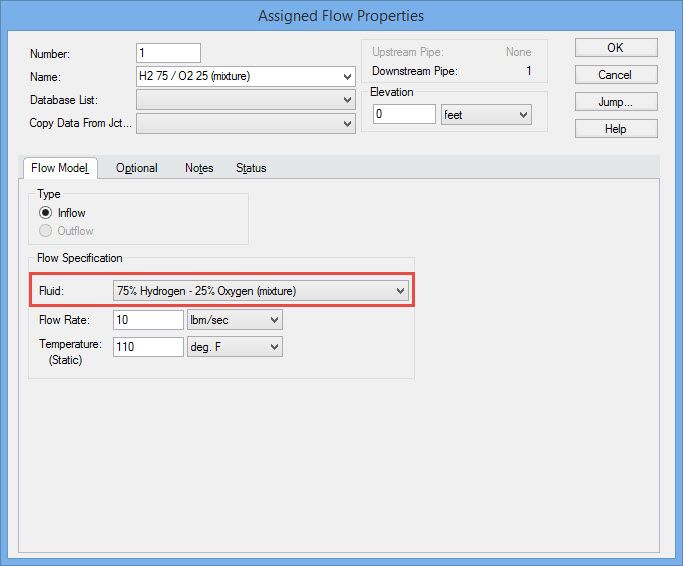

Finally, each specific fluid for each fluid stream will be chosen in the drop-down menu of each boundary junction (i.e., assigned flow, assigned pressure, or tank). The rest of the boundary condition input will be defined as normal (i.e., flow rate and temperature for an assigned flow junction as a supply boundary). Note that in this system, the Gathering Tank J11 is the system discharge, but a specific fluid still needs to be defined. However, it will NOT be used in this case since the properties in the upstream pipe will be determined by the dynamic mixing calculations.

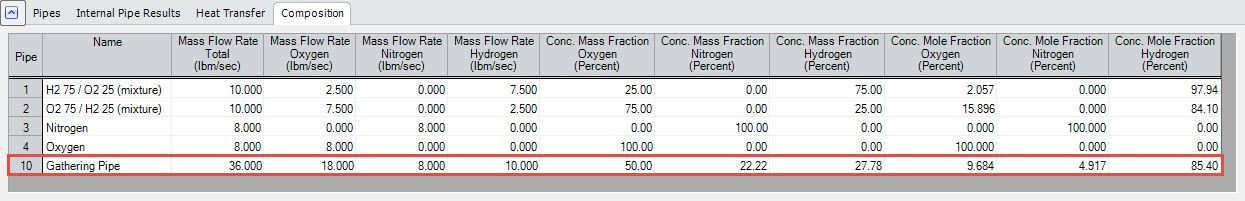

After the model has been ran, a new tab will appear in the Output window in the Pipes and Junctions sections that will display the resulting output information in regards to the fluid compositions. As seen below, the total mass flow rate, individual component mass flow rate, and resulting mass and mole fractions are determined.

Overall, dynamic mixing is one of the many unique and powerful capabilities of AFT Arrow and the Chempak Database must be used in order to take advantage of the dynamic mixing capabilities.

Comments