AFT Blog

Putting Out Fires with AFT Fathom's NFPA Calcs & GSC

If you are performing a hydraulic analysis on your fire system, chances are high that you are working hard and maybe scratching your head in order to adhere to the NFPA codes. The good news is that you can streamline the calculations outlined in the codes with AFT Fathom!

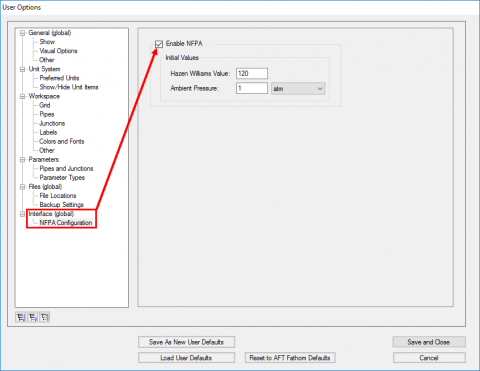

NFPA 15 is the standard for fixed water spray systems that are used in fire protection. AFT Fathom has been able to perform all the standard hydraulic calculations for a fire protection analysis for a long time, including the usage of Hazen-Williams factors. But now with AFT Fathom 9, you can easily generate the specific NFPA report that is required by the standard directly within AFT Fathom. In order to perform these calculations, you will first need to turn on the NFPA reporting with the User Options in the Tools menu, as shown in Figure 1.

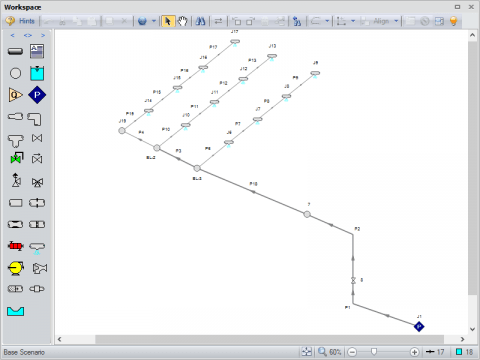

Next, you can build a simple spray system like that in Figure 2.

The fittings in the system can be defined with either standard K factors or with equivalent length methods. After the system is built and all the pipe and junction input is fully defined, you will need to create at least one group for your NFPA analysis. The reason why you will need to create a group is because the NFPA code requires the report to document the hydraulic calculations for the spray nozzle that is the hydraulically most remote from the supply in a continuous flow path.

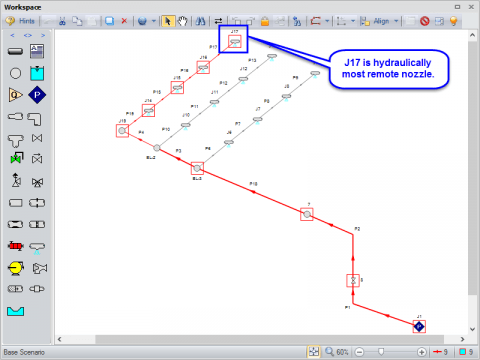

But here lies the issue...Sometimes, (probably most of the time), it is not very easy to determine which spray nozzle is hydraulically the most remote nozzle. So in Figure 2 above, even though J17 appears to be the furthest away from the supply pressure, it may not have the most hydraulic resistance in that flow path. This is where using the AFT Fathom GSC (Goal Seek & Control) module is extremely helpful!

The AFT Fathom GSC module allows an input parameter to be automatically varied until a desired goal is reached. Manual iteration for one goal and variable is easy enough usually, but GSC really shines when you have multiple goals and variables.

For this case, the AFT Fathom GSC module can easily help you pinpoint which spray nozzle is the hydraulically most remote nozzle. For a fire system each spray nozzle must be able to deliver a minimum flow requirement. In order to ensure that each spray nozzle delivers the minimum flow requirement, something in the system must be changed in order for that to happen. The easiest (and probably the best) way is to iterate on the supply pressure.

As the supply pressure increases, each spray nozzle will deliver more and more flow, and once ALL spray nozzles are delivering at least the minimum flow, then the nozzle that is delivering exactly the minimum would be the most remote nozzle. Here's how you would setup this calculation using the GSC module to streamline this process.

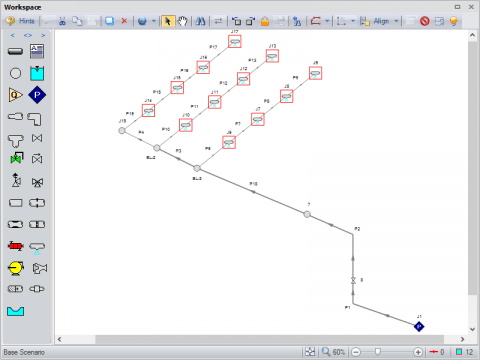

1. Select all the spray nozzles in the system and create a group and give them a name, such as "Spray Nozzle Group".

2. Once selected, go to the Edit menu and then create a group for these nozzles. Here's a blog that briefly describes how to go about this process of creating a group.

3. Next, you can activate the GSC module by going to the Tools menu and then selecting "Activate Modules" and checking the box for GSC. Once activated, it needs to be turned on for the analysis which can be done with the Analysis menu. After the GSC module is turned on, the goals and variables then need to be defined.

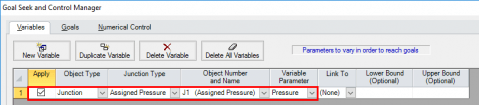

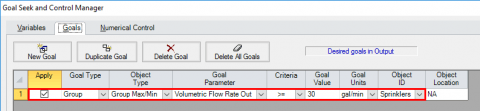

4. In the Goal Seek and Control Manager, the Variable is fairly straight-forward as shown in Figure 4 where you will select the assigned pressure junction to modulate the supply pressure. Then on the goals tab, shown in Figure 5, the type of goal will be a "Group Max/Min" goal and once that option is chosen, you can select your group of spray nozzles and that group goal will ensure that the minimum flow requirement for that group is met.

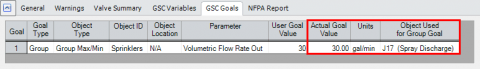

Once the analysis has been run, the required supply pressure to deliver the minimum flow requirement can be determined. As you can see from the goal results on the GSC Goals tab of Figure 6, the spray nozzle that receives the minimum flow requirement is pinpointed as the hydraulically most remote spray nozzle.

Now that we know which nozzle is the most remote, we select a continuous flow path of pipes from the supply pressure all the way to that spray nozzle as shown in Figure 7. After the flow path has been selected, a Group will be created for it so the NFPA report can be generated for this flow path.

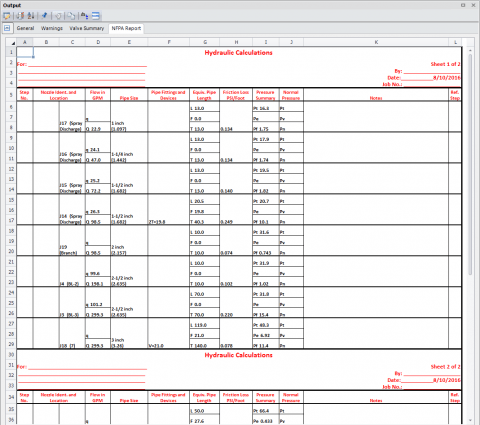

The NFPA calculations then need to be enabled for use from the Analysis menu. Then simply run the model and go to the Output results and select the "NFPA Report" tab in the General section of the Output window and the NFPA Report will be displayed as shown in Figure 8.

And that is all there is to it! So in summary, turn on the NFPA calculations in the User Options window. Build the fire system model. Create a group with all the spray nozzles and use the AFT Fathom GSC module to determine which nozzle is the hydraulically most remote. Once that nozzle is determined, select a continuous flow path from the supply source to the most hydraulically distant nozzle and create the group for the NFPA calculations. Run the model and view the NFPA Report and prepare it for your official NFPA analysis.

Go forth now and put out many fires with AFT Fathom!

Comments 2

I have AFT Fathom Version 9 (2016.01.20) but when I select Tools, User Options then I don't see NFPA configuration option in it unfortunately.

Hi Pavlo, the best thing for you to do is to update to the latest release of AFT Fathom 9 which can be downloaded here, https://www.aft.com/downloads/current-versions/aft-fathom. The NFPA reporting features were not implemented until a later release with AFT Fathom 9 which was after the release you are using.

Also, updating to the latest release will not only allow you to work with the NFPA capabilities, but it will also contain all of the updates we've made to the calculations and reporting over time.

Thanks Pavlo and take care!