AFT Blog

Get in Control with Control Valves

When to use a control valve junction

First let's talk about how the control valve junction is intended to be used. There are two ways control valves can be used:

1) To model an actual control valve which is modulated based on a measurement near to the valve

In this case you should choose the valve type that best represents how the control valve is modulated and define a setpoint.

2) To size a non-controlling element such as an orifice or valve in the model

In this case define the control valve setpoint based on the sizing flow or pressure. After running the model you can then look at the control valve outputs to get the required information to select a control valve. Check out this blog on using a control valve for sizing for more info on where to find sizing outputs for the control valve.

When not to use a control valve junction

One common mistake that we often see users make is to use the control valve junction to force a specified flow or pressure to be achieved in a line which does not or will not have a modulating element in the actual system.

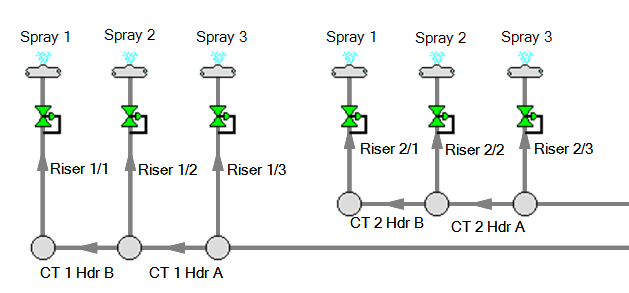

For example, consider a case where an engineer has measured flow rates and pressures at nozzles that are exiting the system. It is tempting to model the nozzles by using a control valve to enter the measured flow rate, and spray discharge junctions to represent the nozzles as shown below in Figure 1. However, if you model the system as shown in Figure 1 you are artificially forcing the model to give the pressure and flow that you measured by adding a large pressure loss to the nozzle lines where a pressure loss does not actually exist.

Instead of forcing the flow to match as described above, the model should be built to reflect the system as well as possible, after which the pressure losses in the pipes can be calibrated to achieve the expected flow rates. For the model in Figure 1 it would be recommended to not use control valves and instead calibrate the piping/nozzle losses to achieve the expected flow rates. An example of calibrating the frictional losses can be found in the AFT Fathom help file.

How control valves are solved for

The control valve junction allows you to model a valve that will modulate its position to fix the flow rate, upstream pressure, downstream pressure, or pressure drop across the valve. Note that for the upstream and downstream pressure setpoint options Fathom will control based on the pressure directly at the inlet or outlet of the valve, although in reality the pressure transponder would not be directly at the valve entrance/exit.

When the model is run Fathom will iterate on the pressure loss at the valve until the user-specified setpoint is met. Fathom will allow the valve loss to be as large or as small as needed to meet the user setpoint.

What happens when a control valve can't control?

In reality if a control valve is not able to reach the programmed setpoint the valve will either fully open or fully close, depending on what setpoint the control valve was trying to meet and the pressure distribution in the system. See the chart below for a summary of when the valve would become fully opened or fully closed.

| Valve Type | If Upstream Pressure Insufficient | If Downstream Pressure Excessive |

| Flow Control Valve |

Open Fully | N/A |

| Pressure Reducing Valve | Open Fully | Close |

| Pressure Sustaining Valve | Close | Open Fully |

| Constant Pressure Drop Valve | N/A | N/A |

In Fathom if the setpoint is not able to be met there are two results that may occur:

1) Fathom will set the control valve as fully open or fully closed as would happen in reality

2) Fathom will add pressure at the control valve to force the valve to control

By default Fathom will do option 2 above and force the valve to control. Note that while option 2 is physically unrealistic, the pressure added by the control valve can be used to troubleshoot why the control valve could not control. Forcing the control valves to maintain control can also help models converge in cases where multiple control valves would not be able to maintain control.

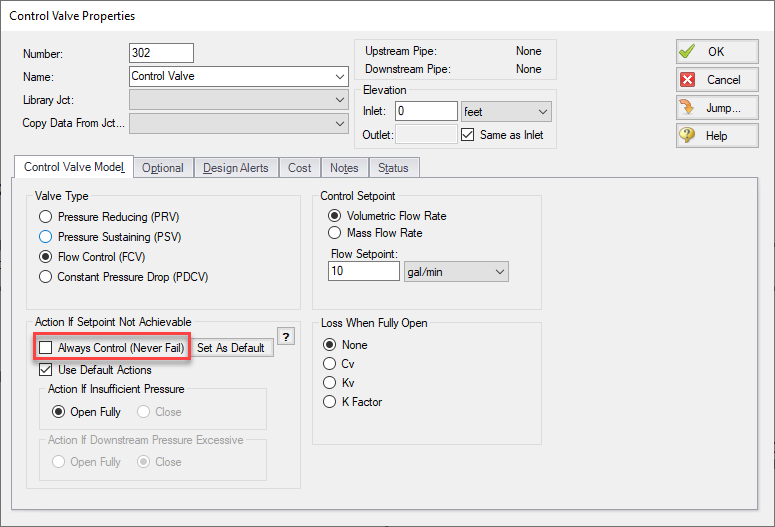

The control valve option to always control can be turned off in the Control Valve Properties Window by unchecking the "Always Control" item as shown in Figure 2 below.

Reference Pressure warnings in AFT software

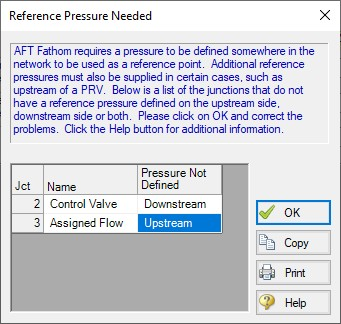

One last common warning you may encounter when using control valves is the Reference Pressure warning shown below in Figure 3.

Using control valve junctions inline with each other or other controlling elements can cause situations where the model is unsolvable because the pressure is not defined for certain sections of the model. You can think of it this way – if you were told to solve by hand for the pressures at the inlet and outlet of a pipe and were only given the pipe size and flow you would only be able to solve for the pressure drop over the pipe, but not the actual inlet or outlet pressures. A similar situation can happen if a flow control valve and fixed flow pump are used in series. Check out our help file topic on Reference Pressure for more information on how to resolve reference pressure warnings.

This blog covered a variety of basic control valve concepts, but didn't get to everything. For more information on control valves visit AFT's Help Sites where you can find product documentation, examples, and more.

Comments