Slurry Pumping Solutions: Model and Optimize Pump Systems

Engineering & Mining Journal: Model and Optimize Pump Systems

Applied Flow Technology (AFT) released its AFT Impulse 9, with improved ability to animate design alternatives, improved modeling tools, a streamlined setup, and new library manager. AFT’s Impulse 9 can be upgraded with the Settling Slurry (SSL) module that allows users to simulate settling slurries.

“Impulse 9 is a powerful dynamic simulation and analysis software used to calculate pressure surge transients in liquid piping systems caused by waterhammer,” AFT said. Among other things, it allows the user to “easily model a wide range of system components and surge devices,” the company said. It helps the user to “understand the transient response of your system, knowing how valves, pumps and other components will dynamically interact with each other.”

The new version offers new tools for waterhammer and surge analysis that can help engineers “mitigate failures and avoid downtime by providing the reliable information necessary to prevent incidents before they happen,” the supplier reported. “While new features and capabilities strengthen this analysis software with each new version, AFT Impulse has been a premier and reliable transient analysis tool since its release in 1997.”

With the new version, the company is offering waterhammer educational events for engineers and others.

Mine engineers can upgrade AFT Impulse with the SSL module to account for hydraulic considerations in systems transporting solids that can settle, an engineer at AFT said.

Developed for use in the hard rock mining space, the SSL module is “an add-on to our incompressible steady state and transient analysis tools AFT Fathom and AFT Impulse,” said Nick Vastine, business applications engineer.

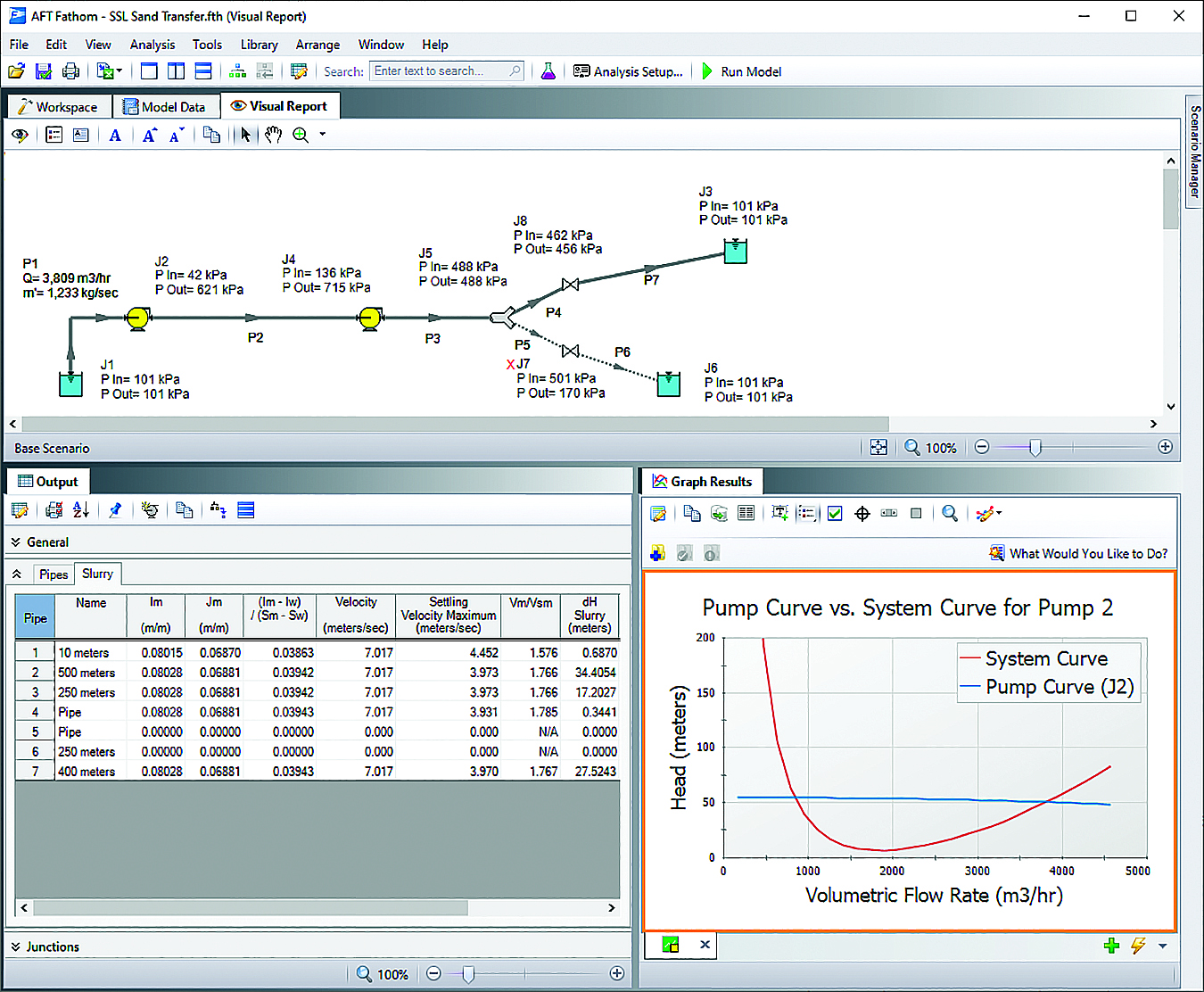

Users can specify solid particles, distribution and concentration. “Users can enter the properties of the solid particles,” AFT said. “The SSL module takes the properties of the solid particles and carrier fluid and calculates the hydraulics of the piping and pumps using widely accepted correlations,” it said. “Correlations are then used to predict the flow, pressure drop and reduced pump performance when pumping solids.”

Modeling the “flow of these slurry mixtures must consider different flow regimes, variations in solids composition, and the effective derating of pump performance among other things,” Vastine said.

The software can generate reports “and additional graphing parameters to assist the user with understanding the hydraulic behavior of the slurry,” AFT said.

The module is based on the Wilson/GIW methodology trusted by industry since 1979,” Vastine said.

“Equipment manufacturers in the mining and dredging industry often provide tools to account for slurry effects during sizing,” he said.

“Our toolset provides additional flexibility to not only size equipment but consider the interaction of those component pieces to design a more comprehensive system,” Vastine said. “The ability to manage and compare these alternatives from a single file ensure engineers settle on a robust solution that operates reliably, efficiently, and safely.”

Designed for use by engineers, the SSL module, within AFT Impulse 9 simulation-and-analysis software, takes the properties of solid particles and the carrier fluid and calculates the hydraulics of piping and pumps. (Image: Applied Flow Technology)

Several features offer heightened accuracy.

“The SSL module can account for the additional hydraulic losses from heterogenous and sliding bed flow regimes,”

Vastine said.

“It can similarly determine the settling velocity of particles and indicate when flow is too slow to prevent those particles from settling out,” he said. “Pumps can also be derated according to ANSI/HI Standard 12.1-12.6-2016 to account for reduced performance with slurries.”

With the module, engineers can “evaluate a large range of operating conditions and combinations to confirm their solids will not settle during operation,” Vastine said. “This ensures equipment like pumps are sized properly and slight variations in system supply or demand will not upset production.”

The application does the “intensive math and file management so engineers can instead focus on analysis and problem-solving,” he said.

Impulse 9 and the SSL Module advance the company’s mission “to empower engineers to intelligently design fluid transfer systems with innovative tools, education, and service,” he said. “Our tools, like the SSL module, ensure engineers can design their system to be safe, reliable, and efficient.”

This article is published in the September 2022 issue of Engineering & Mining Journal. Read the full story.