Many of you are aware that AFT released the ANS module for AFT Fathom and AFT Arrow last year to help engineers minimize the cost of their system and maximize reliability. You can check out this blog I wrote last year for a quick recap on the capabilities of ANS. Let's talk a bit more about what information you need to use the ANS module by introducing each of the panels that can be found in the Sizing Window on the Sizing Navigation Panel, as can be seen in Figure 1.

Sizing Objective – What do you want to minimize?

The first input the ANS module will ask for is an objective. While the goal is typically to minimize the system cost, there are different ways to go about achieving this. Minimizing the monetary cost directly for the components in the system would be the most direct approach, but this is also complex as cost information for every component is typically not available to engineers during the design phase.

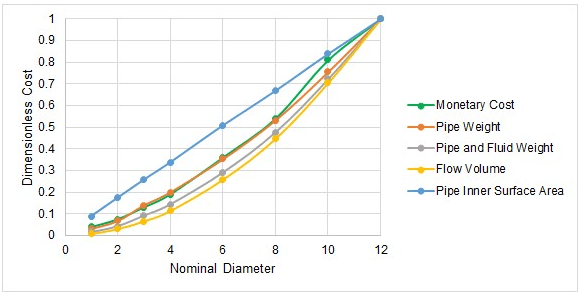

In many cases simply minimizing the pipe weight for the system will be equivalent to minimizing the monetary cost. Other options such as minimizing flow volume are also available for use. Depending on the constraints for the system it may be useful to minimize the volume of the piping system instead. Figure 2 shows a dimensionless comparison of different sizing costs using Steel ANSI Schedule 40 pipe. It can be seen here that in this case the pipe weight and monetary cost lines show the best correlation, though that may not be true for all pipe materials/schedules.

Sizing Assignments – What do you want to be sized?

For this panel the user simply chooses which pipes Fathom/Arrow should consider when minimizing cost. The user can also create common size groups, which will force all pipes in the common size group to be the same size. Creating effective common size groups will help to reduce the run time for the model and reduce the complexity of the design by limiting the number of separate pipe sizes in the design. For example, the suction piping segments for a group of parallel pumps could be added to one common size group, while the discharge piping for those pumps could be added to another group, since it would be logical for those pipes to have equivalent sizes.

Candidate Sets – What pipe materials and sizes can be used for the system?

A candidate set is required to tell Fathom/Arrow what pipe or duct sizes can be used for each pipe/duct in the system. Generally the rule of thumb is that the more pipe sizes you include in the candidate set, the more flexibility for Fathom/Arrow to find a lower cost solution. Of course, more available sizes can also lead to longer run times. For a simple model including all possible pipe sizes is fine. However, for more complex models limiting the candidate set may be desired to obtain a faster solution.

Design Requirements – What conditions must be enforced in the system?

Design Requirements are important in the ANS module to make sure that the final design proposed by the ANS module has a minimal cost and will operate successfully. Depending on how the model has been built, some requirements for the system may be inherently defined in Fathom/Arrow as boundaries for the system. For example, there may be a required pressure and flow at the system outlet. To account for this, you may represent the outlet boundary as an Assigned Pressure junction, which will inherently ensure that the minimum pressure is achieved at the outlet. You could then add a design requirement at that point to ensure that the minimum flow is achieved, or vice versa. A design Requirement will provide more flexibility than a boundary condition, as the design requirement does not fix the flow rate to the minimum/maximum value, but instead allows that number to vary, as long as the minimum/maximum condition is met. Thus, for each design condition, the engineer should consider whether a boundary condition or design requirement would best account for that condition.

Sizing Method – What calculation method should be used?

The last panel which will always be required is the Sizing Method. Typically, the user should first run the model using the continuous sizing type, then run the model using the discrete sizing type as a comparison. If the two solutions are not similar, then the engineer should choose a different Search Method which may be more suited for the analysis. Running the model using multiple different searching methods is recommended to find the best system design, as it is typically not clear which method will be best suited for each system.

Conclusion

Once the complete model is built it is possible to define all sizing inputs described above in just 15 – 20 minutes to perform a simple pipe weight sizing. All you will need to know is what type of cost you want to minimize, which pipes you would like to size in the model, what pipe materials/schedules you want to consider for the system, and what design requirements must be met. You can then adjust the sizing input to improve the run time by linking the size of some pipes using common size groups and testing different sizing methods.

With even simple inputs large savings can be found on the initial cost for building the system. To see and/or build examples, check out the Example Help file, accessed in Fathom or Arrow from the Help menu. You can also check out this video tutorial which walks through an example of sizing a system based on pipe weight.