AFT Fathom 8 can be used to quickly and easily model multiple pump configurations with different pump speeds and impeller sizes. First, determine a particular pump curve to use from either a manufacturer’s pump curve or pump curve verification test data. Next, determine new pump curves for head and flow using the affinity laws considering either a change in pump speed or impeller size. The multiple pump curve data sets will then be entered for each particular pump configuration.

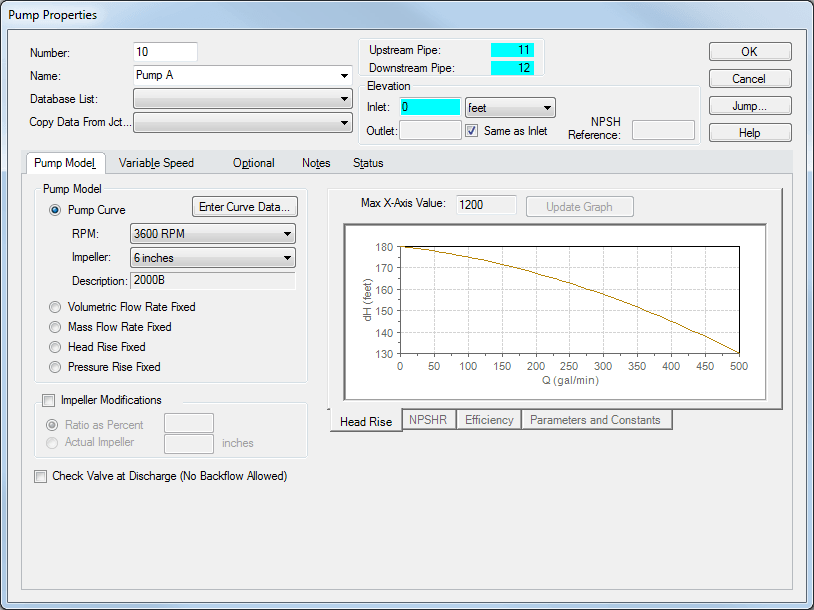

In Figure 1 (click on the image to see it larger), there are a few pump configurations that have already been defined. Suppose one more impeller size of 6 inches needs to be defined for the 3600 RPM pump. Click the “Create” button, and then specify the RPM, Impeller Diameter with units, and a Description such as a pump’s model number. Enter in the pump curve data points; click “Generate Curve Fit Now,” then click “Update Configuration Now.”

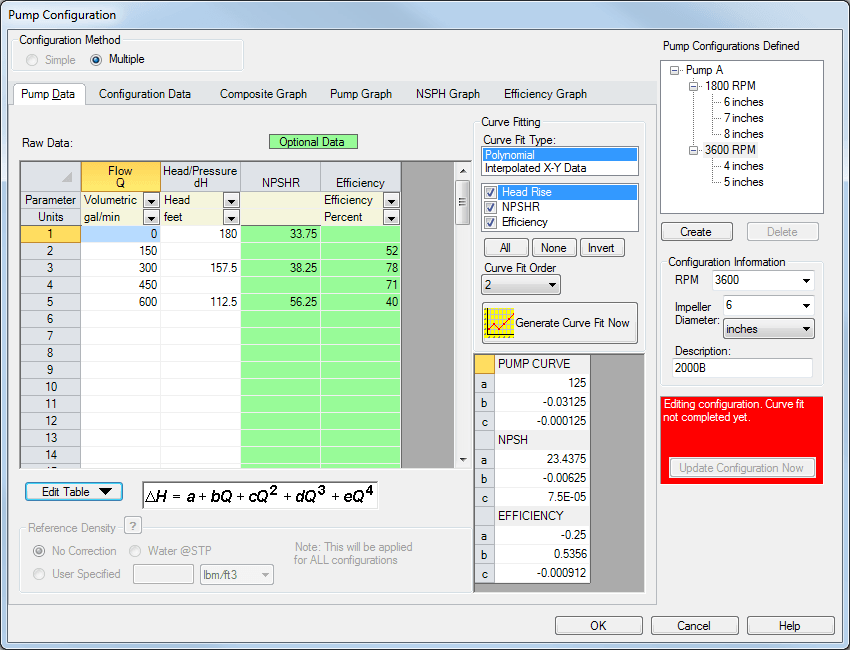

After the multiple pump configurations have been developed, they can be chosen in the Pump Properties window as in Figure 2. When the specific RPM and Impeller size are chosen in the drop downs, the appropriate description and pump curve will be displayed. Figure 2 shows the 6 inch impeller size for the 3600 RPM pump configuration that was added.

Overall, the capability to model multiple pump configurations will save an extensive amount of time for the engineer! Rather than manually entering a new pump curve for each pump and for several different scenarios, the pump curve only needs to be entered ONCE and then the desired configuration can be quickly and easily chosen in the Pump Properties window.